Rick Jones Slows Things Down With Modernized ’49 Chevy Pickup

Rick Jones has spent the better part of 30 years of his life working to hone and perfect the art and the business of drag racing chassis, in that time becoming one of the most revered and respected builders in the sport. Drag racing has been his life’s work, and when he’s not at home in Illinois overseeing his chassis and performance parts operation, he and son Rickie are traveling the country calling the tuning shots on Erica Enders’ Elite Motorsports Pro Stock machine.

While Jones lives and breathes the quickest and fastest motorsport on earth, however, he still knows how to slow it down when away from the track, and that’s illustrated through his delight in every-day muscle cars, pickup trucks, and street rods. Through his extensive Quarter-Max chassis mail order division, Jones has been steadily increasing involvement in this popular marketplace, placing components for Sunday drivers and car show queens in the company’s catalog alongside those destined for 4,000-horsepower Pro Modifieds.

When Jones purchased a 1949 Chevrolet pickup six months ago as a fun little driver, he found it the perfect “storefront window” to display some of the race-proven components found in the Quarter-Max catalog, while at the same serving as the inspiration for development of new parts and pieces.

"We’re developing and offering more and more parts for the street market, just like we do with drag racing." – Rick Jones

“We’re just trying to offer more and more parts for the street market, just like we do with drag racing,” Jones says. “Anything that we can develop that we see a need for in the racing market, we do — be it tools or parts, or anything else.

“We do sell products to customers in the street market, and I have an interest in hot rodding and street rodding, so my belief was ‘why not go ahead and build the parts?’ The manufacturing side requires the same machines that we already have here in our shop, so it made sense to get involved.”

When Jones purchased the pickup, he tells us the front suspension was already complete, and just in need of some re-working. But out back, it had leaf springs and a Chevrolet 10-bolt rear end housing that he says “rode rough” and simply “wasn’t as nice as I wanted it to be.” With that, he decided it would be an excellent platform to research and develop parts on.

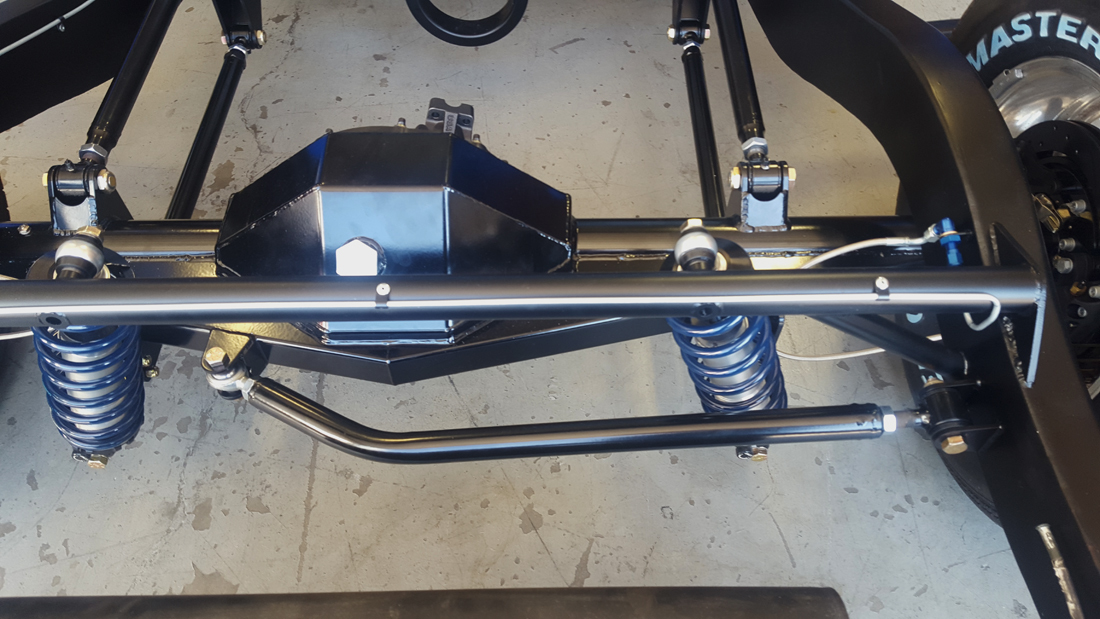

One of the products that was a direct result of Jones’ pickup was a new rear end frame box-in kit, which Quarter-Max’s fabricators created a template for and cut from 11-gauge mild steel on a water jet in-house. These kits, as any hot rodder can attest, strengthen up the OEM framerails, making them appear like box tubing when welded and finished. The plates box-in the frame from the crossmember at the back of the cab to the frontside of the rear crossmember. Their addition is particularly valuable if you plan on running a four-bar rear suspension system and coilover shocks or air bags, as Jones has.

This particular frame box-in kit will fit 1947-54 Chevrolet and GMC trucks, and Jones shares that other kits will soon be in the works for other makes and models of vehicles, allowing greater flexibility, whether you’re building a race car or a show car.

“If you want to backhalf your truck like mine, you can just cut off all of the original suspension components and this four-piece kit will box in the framerails on both sides,” Jones explains. “It works really well … you can grind down the original frame or sandblast it, weld the plates in place, sand down the welds, and it looks like nice clean box tubing. It makes the frame stronger, so that when you install your new shock mounts and four-bar crossmember, the frame is stronger and better-looking.”

From there, a four-bar rear suspension package, panhard bar, adjustable shock mounts, and polyurethane rod ends, all made in-house at Quarter-Max for the four-link, were installed.

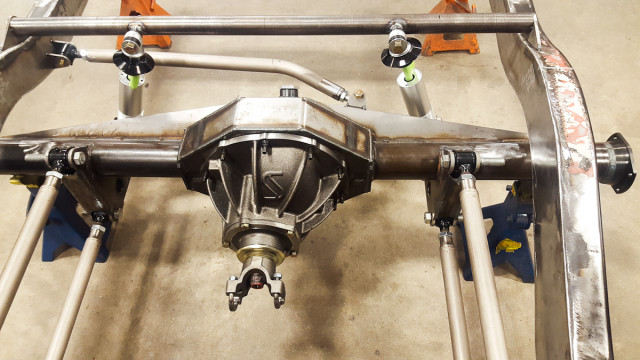

The truck also sports Quarter-Max’s 9-inch sheet metal rear end housing with their in-house welded back brace for support. The housing, which is a popular amongst racers and street car enthusiast alike, is constructed in 45 or 60-inch widths for varying tire and wheel sizes, of either mild steel or 4130 chrome-moly. Quarter-Max has fabricated 1/4-inch thick face plates for the housing on a CNC mill to give exacting stud locations, so that each and every housing is a perfect fit for your third member. The housing covers are cut on a water jet from a single piece of material and formed on a CNC brake in-house at Quarter-Max. These housings can be custom ordered with ends, brackets, and tabs to customer specifications to fit in any vehicle.

“It’s a lot nicer than the stock housing, it’s very, very strong, and it looks great. It’s also nice and straight, so when its done, it really adds to the performance. All of this stuff does matter on how a vehicle handles, whether you’re on the race track or on the street,” Jones explains.

Strange Engineering, of which Quarter-Max is a dealer for, is also well represented on the project. The truck sports their 9-inch nodular third member with a set of 3.50 gears and posi traction, along with 31-spline axles, double adjustable shocks, and a steel driveshaft. Jones utilized Quarter-Max 360-degree, 11 x 8.5-inch rectangular tube driveshaft hoops for the project, which are made from a heavy duty 1 by 2 by 1/8-inch wall rectangular mild steel tubing and TIG welded for durability. These hoops are suited to both street and race cars.

“A lot of guys that build outlaw or bracket cars with 2×3 back half frames will find the square tube driveshaft loop more suitable for their applications. It’s popular with anyone that uses the stock floors — guys with a 2 by 3 drop front crossmember find that this fits better than round tubing does,” Jones explains.

“There’s no wrinkles or kinks in these hoops anywhere, so they’re a really nice piece,” he goes on to say.

Jones’ truck has a single 360-degree hoop, welded to the front crossmember via a pair of 2 x 3 square tubes on each side, behind the cab.

Jones went with a set of Willwood disc brakes for the stopping power.

“Following the development of components on this truck, it’s created a lot of spin-off products. We should have about 25 new kits in the near future that we can trace right back to what we did on this project.” Jones affirms, however, that many of the parts, specifically those for the rear suspension and driveline package, will be largely universal and compatible with a wide range of vehicles types, makes, and models.

So how does it ride, you might ask? “It rides beautifully,” says Jones. “Just like a brand new truck. It’s fun to drive….I drove it home last night and back to work this morning.”

Jones has a 350 cubic inch Chevrolet small-bock crate motor in the truck, backed up by a Turbo 350 transmission. And while it’s enough to bark the tires — as Jones confirms he’s tested — he shares that he’s not driven to find out what it can do at the track, choosing instead of bask in the simple joys of owning and driving a vehicle with the aura of yesteryear and the modern qualities of today. Simply put, he’s content to just slow things down every now and then.

“The truck came out great, and it’s been a lot of fun,” he says. “It’s always nice and refreshing to do something new.”

Recent Posts

-

Mike Castellana Wins 2023 NHRA Pro Mod World Championship in RJ Race Cars built Camaro

Mike Castellana clinched his first career NHRA world championship in the FuelTech NHRA Pro Mod Drag …Nov 20th 2023 -

Erica Enders Wins 2023 NHRA Pro Stock World Championship in RJ Race Cars built Camaro

Winningest Woman In Motorsports Wins Second Consecutive Title For Elite MotorsportsPOMONA, Calif. (N …Nov 17th 2023 -

Get 2023 Black Friday Deals Now at Quarter-Max!

Get Black Friday Deals Now at Quarter-Max!Don't miss the biggest SAVINGS event of the year at Quarte …Nov 16th 2023